BURNER IGNITION TESTER

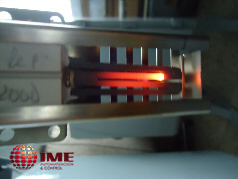

Test equipment designed to safely test functionality and operation of the burner ignition by means of hot surface igniters in gas ranges. The tester detects the flame in burners and oven by a sensor sensitive to ultraviolet (UVTRON R2868 and drive circuit, HAMAMATSU), also recording the passage of electric current through the ignitor. Likewise, it is possible to detect with the same sensor due to its sensitivity, the ignition of resistive elements by its UV emission.

· Test ignition in gas stoves

· Test ignition of electrical stoves

TEST EQUIPMENT FOR HOT SURFACE IGNITORS (ISC)

Hot Surface Ignitor (ISC)

So far, the ISC used in stoves, clothes dryers, heaters, etc. have improved mechanical strength characteristics, resistance to cracks and fissures, thermal shock resistance, chemical resistance, resistance to deformation at room temperature and high temperatures, however, during its assembly in the production line are subjected to management efforts that can cause complete or partial fractures on the ignitor, still need to check the functionality of ISC after placement. For ISC test we developed three types of equipment:

1.- Electric resistance tester

In the ISC test by its electrical resistance, the resistance most be measure at room temperature, the acceptance range is usually from a low resistance value, As indicated in the data sheet of the manufacturer in ohms. while the value is within the range that does not matter as long as the igniter is not open or in short, any value outside this range indicates that the part under test should be rejected. Must absolutely never be effected the resistance test if the ISC has been previously energized with voltage of 120 VAC, due to the change in resistance with temperature, the electrical resistance of the igniter device will decrease as the surface temperature rise.

The integrated measuring equipment has a range of 0-2000 ohms and has 2 programmable set points to define the range of acceptance of measurements.

We have equipment to test 1, 2 or 3 igniters. Electrical resistance test is performed in 6 seconds.

2.- Tester for crack detection

Another way to check the functionality of a hot surface igniter is through indirect detection of existing cracks produced in the material of the igniter. The cracks are manifested in different ways, microcracks, fissures with bridging, and fork deflection, cracks plucking branching cracks, resulting nonlinear changes in the electrical resistance of the igniter, manifested by applying the operating voltage in the form of distortion of electric current wave passing through the ignitor and presenting variations with time, presenting sometimes the demise of the distortion as reach a high temperature the ignitor.

This equipment is capable of detecting the crack in a span of three seconds.

3.- Resistance tester and crack detection

Depending on the type and shape of the cracks, the igniter can maintain a resistance value that does not reflect the failure of the same, so, most likely to ensure a detection of faulty igniters, we integrated in one test equipment resistance and crack test sequentially. The testing time for the resistance measurement is 6 seconds and crack detection test time is 3 seconds.

TESTER FOR ELECTRICAL SAFETY TESTING

This tester is an integrated equipment developed to perform electrical safety tests that meet international standards IEC (International Electrotechnical Commission), EN (European Norm) and NOM (Mexican Official Standards). Its design is based on an industrial PC + PLC and a monitor 19" touch screen LCD.

Depending on your requirements we can integrate the equipment to tests and measures:

· Dielectric AC and / or DC (Hypot AC and / or DC)

· Functionality (Measurement of electrical parameters: voltage, current, power consumption)

For more information about instruments for electrical safety testing visit the website at ASSOCIATED RESEARCH, INC.

EQUIPMENT MANUFACTURING FOR MEASUREMENT OF ELECTRIC PARAMETERS

In the manufacture of appliances one of the essential tests is to measure the power consumption of the devices in the production line, in order to ensure proper operation and compliance with standards that reflect product quality and customer satisfaction.

Voltage sources and measurement:

Our equipments "AC Voltages Sources" control the connection and disconnection of voltage 120VAC or 120/240VAC manually or automatically (controlled by a programmable time), additionally performed measuring voltage, power consumption of current line and neutral, and the power of the device under test.

We have models with 3 different ranges detection for electric power consumption.

The measuring ranges can be specified according to your requirements.

9 VDC Power Supply

Power supply assembled within an industrial enclosure for applications requiring testing on production lines for devices that operate on 9V batteries.

The input voltage is 120 VAC and has start and stop buttons to connect the output voltage of 9 VDC to the output connector. The output voltage is protected against short circuit by its electronics and disconnected by a relay.

Features:

| Input voltage | 120 VAC ± 10% a 0.25 A. |

| Output voltage | 9 VDC ± 1% |

| Current Capacity | 2.45 A máx. |

| Load Regulation | ± 1% (del 10% al 100% de cambio en la carga) |

| Short Circuit Protection | Continuous |

Cycle life test equipment

We design and manufacture electromechanical equipment for testing of cycle life and fatigue to assess the durability of a product, simulating in a short time the behavior that will be the product over its lifetime according to the conditions and customer usage. Contact us to provide multiple solutions to your problem..